MX Touch Finger

MX Touch Finger

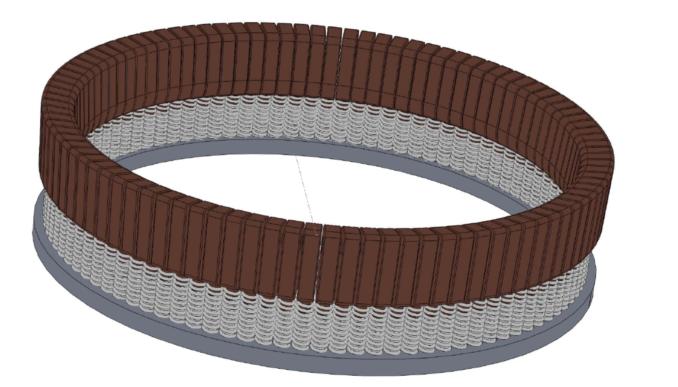

As the core component of conductor connectors, the connecting contact finger directly affects the current carrying capacity of the product. From the conventional plum blossom contact finger, spring contact finger, strap contact finger and other improvements and optimizations to the current busbar specific MX contact finger, its structure is simple and its performance parameters are high. Through a series of experiments, it has been proven that the MX contact finger is more in line with the requirements of large stroke and high load busbar products, The deflection angle of MX contact finger can reach ± 3 °, with a mechanical lifespan of up to 30000 times and a maximum current capacity of 15000A. All parameters are higher than those of conventional contacts currently used domestically and internationally.

MX Touch Finger Structure

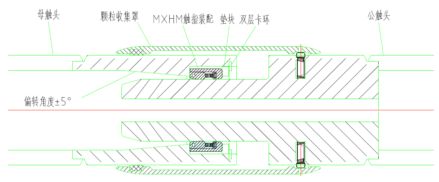

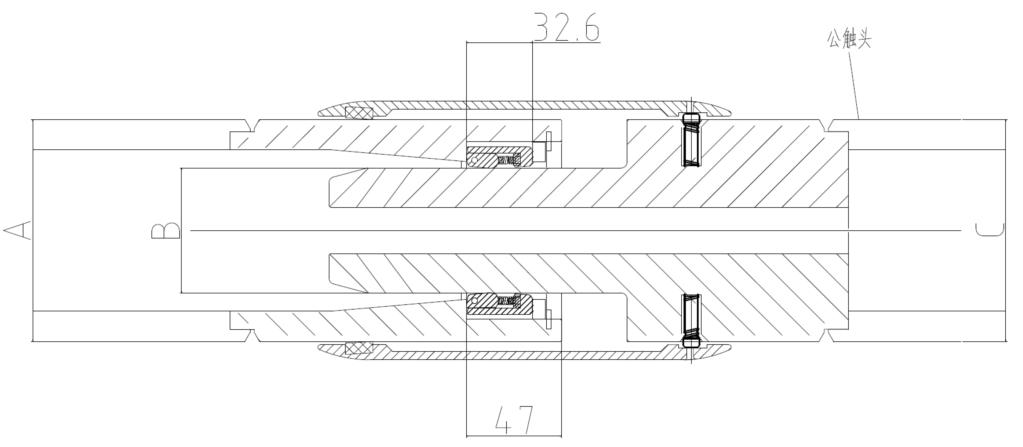

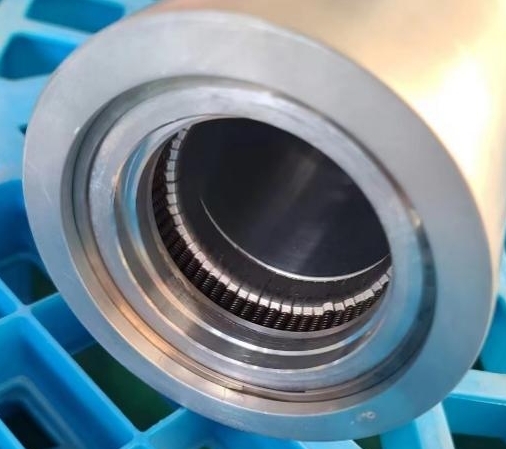

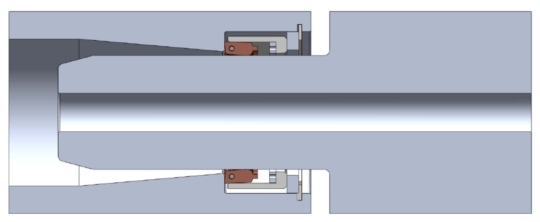

1. The MX contact finger connection structure is shown in the following figure: it consists of a female contact, a male contact, a particle collection cover, a cushion block, a double-layer snap ring, and an MX contact finger assembly, with a ± 5 ° deflection angle set on the inner side of the female contact.

2. MX finger structure: composed of finger pads, pressure springs, positioning rings, positioning sleeves, and finger seats.

MX Touch Finger Assembly

MX Touch Finger Structure Diagram

3. Main technical indicators

Distance of contact movement:+/- 40mm (calculated from installation position, can be adjusted according to customer requirements)

The movement distance of special contacts inside the corrugated tube:+/- 200mm

Maximum deflection angle of the contact:+/- 3°

Number of touch points: Adjust according to current requirements

Flow capacity of each touch finger: 90A

Flow capacity: 15000A

Short circuit current capability: 90kA/3s

Contact resistance: 2.5 µ Ω

Selection of supporting structure for MX touch finger

The main structural selection dimensions for the supporting structure of our MX touch finger, in addition, our company can also

Design separately to match the customer's existing products and needs.

序号 | 通流能力 | 电压等级 | A(mm) | B(mm) | C(mm) |

1 | 3150A*1.1 | 220kV | 102 | 60 | 102 |

2 | 4000A*1.1 | 220kV | 115 | 67 | 115 |

3 | 5000A*1.1 | 220kV | 145 | 97 | 145 |

4 | 5000A*1.1 | 550kV | 150 | 102 | 150 |

5 | 6300A*1.1 | 550kV | 170 | 122 | 170 |

6 | 6300A*1.1 | 800kV/ | 180 | 140 | 180 |

7 | 9000A*1.1 | 800kV/ | 200 | 160 | 200 |

8 | 6300A*1.1 | 1100KV | 180 | 140 | 180 |

9 | 9000A*1.1 | 1100KV | 200 | 160 | 200 |

Life test

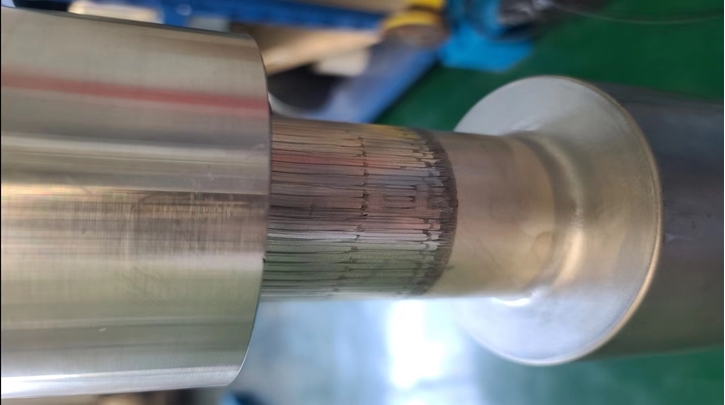

Status after 30000 mechanical lifetimes

Advantage

① The MX contact finger can achieve a maximum ± 3 ° contact deflection angle, making engineering layout more flexible and suitable for various complex curve conditions such as high drop vertical shafts and inclined shafts.

② Due to the larger deflection angle of the MX contact finger, it can effectively eliminate the conductor stress caused by thermal expansion and contraction of the cylinder body when the ambient temperature changes, ensuring that the insulation components are not subjected to abnormal stress.

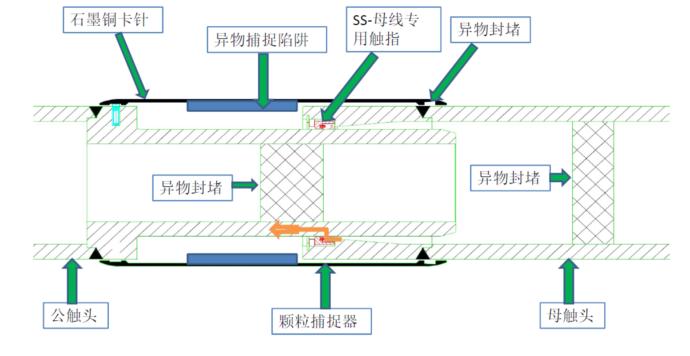

③ The MX connection contact is equipped with a particle capture structure, which can effectively collect particles generated by contact finger friction during operation, ensuring the cleanliness requirements of the product interior and improving the product's anti pollution ability.

The 4MX touch finger has the characteristics of low contact resistance, easy installation, strong installation fault tolerance, low wear, and high lifespan. And it has high reliability and large flow capacity.

Compared to other conventional finger touches

① The conventional plum blossom contact finger, spring contact finger, and watch strap contact finger can only achieve a maximum contact deflection angle of ± 0.5 °, which has great limitations in engineering applications and is restricted in use in complex curve working conditions.

② When using conventional contact fingers in engineering, insulation components may be subjected to conductor stress caused by thermal expansion and contraction of the cylinder due to changes in ambient temperature, and insulation components may be damaged by stress during long-term operation.

③ The contact connection of conventional contact fingers generally does not have a particle capture structure. During long-term operation, the particles and foreign objects generated by the friction of the contact fingers will enter the air chamber with the movement of the contact. If the particles and foreign objects adhere to the insulation, it is highly likely to cause flashover discharge of the insulation.

Assembly diagram of plum blossom or spring contact finger